Revolutionizing Offshore P&A: The Power of LoRaWAN and Satellite for Data Collection

Executive Summary

1. Introduction to Offshore P&A Challenges

1.1 The Imperative of Decommissioning:

1.2 Complexity and Risks in P&A Operations:

1.3 The Cost Burden:

2. Traditional Data Acquisition in Offshore P&A

2.1 Current Methodologies and Their Shortcomings:

2.2 Challenges with Traditional Data Acquisition:

3. The Promise of LoRaWAN Technology

3.1 LoRa Technology Fundamentals:

3.2 LoRaWAN Architecture:

3.3 Advantages of LoRaWAN for Offshore P&A:

4. The Critical Role of Satellite Communication

5. Implementation Strategies

Summary: Bridging the Connectivity Gap

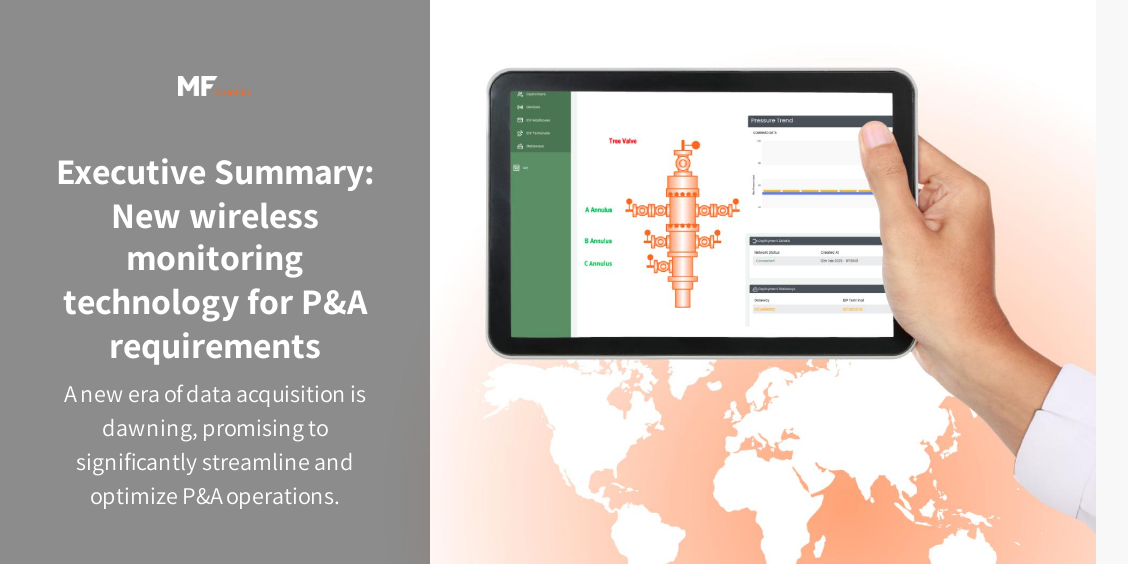

The offshore oil and gas industry is at a critical juncture, facing mounting pressure to responsibly and economically decommission an ever-growing number of aging wells. Plug and Abandonment (P&A) operations, which involve sealing off wells to prevent hydrocarbon leakage, are inherently complex, high-risk, and notoriously expensive. A central challenge within these operations is the efficient and reliable collection of critical data. Traditional data acquisition methods on offshore platforms are often cumbersome, labor-intensive, and prone to limitations, leading to increased operational costs and potential delays. However, a new era of data acquisition is dawning, promising to significantly streamline and optimize these crucial processes.

This paper delves into a groundbreaking innovation: the synergistic combination of LoRaWAN (Long Range Wide Area Network) technology and satellite communication. This powerful duo can transform the landscape of offshore P&A data collection, offering operators an unparalleled blend of efficiency, reliability, and cost-effectiveness. By leveraging the unique capabilities of LoRaWAN for localized, low-power data transmission and satellite connectivity for global reach, this approach addresses many of the historical bottlenecks associated with offshore data acquisition, paving the way for safer, faster, and more economical P&A operations.

1. Introduction to Offshore P&A Challenges

The offshore oil and gas industry is undergoing a significant transformation, with a growing emphasis on environmental responsibility and economic efficiency. As oil and gas fields mature, the decommissioning of aging wells becomes a paramount concern. Plug and Abandonment (P&A) operations are the final phase in the lifecycle of an offshore well, aiming to safely and permanently seal off the wellbore to prevent the uncontrolled release of hydrocarbons into the environment. These operations are not only critical for environmental protection but also represent a substantial financial burden for operators.

1.1 The Imperative of Decommissioning:

The number of wells requiring P&A is projected to increase significantly in the coming decades. Regulatory bodies worldwide are imposing stricter requirements for well abandonment, driven by environmental concerns and the need to mitigate long-term liabilities. The North Sea, for instance, has a vast inventory of aging infrastructure, presenting a significant decommissioning challenge.

1.2 Complexity and Risks in P&A Operations:

P&A operations are inherently complex due to the intricate nature of wellbore architecture, the presence of various downhole obstructions, and the need to achieve a permanent seal in challenging subsurface environments. These operations involve a multitude of specialized equipment, highly skilled personnel, and adherence to stringent safety protocols. The risks associated with P&A include:

- Hydrocarbon Leakage: The primary risk is the potential for hydrocarbons to escape from the wellbore into the surrounding environment, leading to ecological damage and reputational harm.

- Wellbore Instability: Drilling and completion activities can compromise the integrity of the wellbore, increasing the risk of collapse or uncontrolled fluid movement during P&A.

- Operational Delays: Unforeseen downhole conditions, equipment malfunctions, or adverse weather can lead to significant delays, escalating costs.

- Environmental Impact: Beyond hydrocarbon spills, P&A operations can generate waste materials and require significant energy consumption.

1.3 The Cost Burden:

P&A operations are notoriously expensive. Factors contributing to the high costs include:

- Vessel and Rig Time: Offshore operations require specialized vessels or rigs, which incur substantial daily rental costs.

- Specialized Equipment: The use of cementing tools, wellhead removal systems, and downhole logging equipment adds to the capital expenditure.

- Personnel Costs: Highly trained engineers, technicians, and divers are required, contributing significantly to operational expenses.

- Logistics: Transporting equipment and personnel to remote offshore locations is logistically complex and costly.

2. Traditional Data Acquisition in Offshore P&A

Reliable and timely data is the backbone of efficient and safe P&A operations. Decision-making, from wellbore integrity assessment to cement plug placement, hinges on accurate information. However, traditional data acquisition methods on offshore platforms often present significant limitations.

2.1 Current Methodologies and Their Shortcomings:

- Manual Data Logging: Many parameters are still recorded manually, leading to human error, delays in data availability, and difficulty in real-time analysis.

- Wired Sensor Systems: While offering high bandwidth and reliability, wired systems are expensive to install and maintain, especially in retrofitting existing platforms. Their deployment is often restricted to specific, critical areas.

2.2 Challenges with Traditional Data Acquisition:

- Cumbersome Deployment: Installing and maintaining extensive cabling for wired sensors in harsh offshore environments is labor-intensive, time-consuming, and poses safety risks.

- Labor-Intensive Monitoring: Manual data collection requires dedicated personnel, increasing operational expenditures.

- Lack of Real-time Insights: Data often needs to be physically collected, transcribed, and then analyzed, leading to delays in decision-making and hindering proactive intervention.

- Data Silos: Information collected by different teams or systems may not be easily integrated, leading to fragmented insights and hindering a holistic view of operations.

- Limited Reach: Traditional wireless technologies often struggle to cover the entire expanse of an offshore platform, especially in areas with significant metallic structures or where power is scarce.

- High Power Consumption: Many conventional wired and wireless sensors require frequent battery replacement or continuous power, increasing maintenance demands.

These limitations collectively contribute to increased operational costs, potential safety hazards, and a lack of optimized decision-making, highlighting the urgent need for a more efficient and reliable data acquisition paradigm in offshore P&A.

3. The Promise of LoRaWAN Technology

LoRaWAN (Long Range Wide Area Network) is an open standard communication protocol designed for low-power, wide-area networking. It is a key technology for the Internet of Things (IoT), enabling long-range communication between battery-powered devices and network gateways with minimal power consumption.

3.1 LoRa Technology Fundamentals:

LoRa (Long Range) is the physical layer (PHY) or wireless modulation utilized within LoRaWAN. It employs a chirp spread spectrum (CSS) modulation technique, which provides several distinct advantages:

- Long Range: LoRa signals can travel several kilometers in urban areas and over 15 kilometers in rural or open environments, making it ideal for large industrial facilities like offshore platforms.

- Low Power Consumption: LoRa devices are designed to operate for years on a single battery, significantly reducing maintenance requirements. This is crucial for sensors deployed in remote or hard-to-access locations.

- High Interference Immunity: CSS modulation provides robust performance in noisy environments, which are common on offshore platforms with various machinery and radio frequency emissions.

- High Sensitivity: LoRa receivers can detect very weak signals, allowing for greater range and penetration through obstacles.

3.2 LoRaWAN Architecture:

A typical LoRaWAN network consists of four main components:

- End Devices: These are the sensors or actuators that collect data (e.g., pressure, temperature, vibration, acoustic data) and transmit it using LoRa modulation. They are typically battery-powered and designed for low-power operation.

- Gateways (LoRaWAN Concentrators): Gateways receive signals from multiple end devices and forward them to the network server. They are typically connected to the internet via Ethernet, Wi-Fi, cellular, or satellite.

- Network Server: The network server manages the entire LoRaWAN network. It handles data deduplication, routes messages to the appropriate application server, and manages device authentication and security.

- Application Server: The application server receives the processed data from the network server, decodes it, and makes it available to the end-user applications for analysis, visualization, and decision-making.

- Extensive Coverage: A single LoRaWAN gateway can cover a vast area of an offshore platform, reducing the number of access points required and simplifying infrastructure.

- Low Power Consumption: Enables the deployment of battery-powered sensors in hard-to-reach or power-constrained areas, reducing the need for costly wiring and frequent battery replacements.

- Robustness in Harsh Environments: LoRa's modulation technique is resilient to interference, making it suitable for the electrically noisy environment of an offshore platform.

- Cost-Effectiveness: The low cost of LoRaWAN modules and the ability to cover large areas with fewer gateways lead to a lower total cost of ownership compared to traditional wireless solutions.

- Scalability: A LoRaWAN network can easily accommodate thousands of sensors, making it suitable for comprehensive monitoring across an entire P&A operation.

- Security: LoRaWAN incorporates end-to-end encryption at both the network and application layers, ensuring data integrity and confidentiality.

3.3 Advantages of LoRaWAN for Offshore P&A:

While LoRaWAN excels at localized, low-power data transmission across an offshore platform, it lacks the global reach necessary to transmit this data back to onshore operations centers in real-time. This is where satellite communication becomes indispensable, acting as the crucial backhaul link.

- Global Coverage: Satellite communication offers truly global coverage, ensuring that data can be transmitted from any offshore location, regardless of its distance from shore or the availability of other communication infrastructures. This is paramount for P&A operations that often occur in very remote and isolated areas.

- High Bandwidth (for aggregated data): While individual LoRaWAN packets are small, the aggregated data from numerous sensors over time can be substantial. Modern satellite systems offer sufficient bandwidth to efficiently transmit this accumulated data, including sensor readings, diagnostic information, and even low-resolution images or video if required.

- Reliability in Extreme Conditions: Satellite systems are inherently robust and designed to withstand extreme weather conditions, ensuring continuous data flow even during storms or other environmental challenges common in offshore operations.

- Independence from Terrestrial Infrastructure: Unlike fiber optic cables or terrestrial cellular networks, satellite communication is independent of land-based infrastructure, making it ideal for deployments far from shore or in areas without established communication networks.

- Redundancy and Resilience: Satellite communication can serve as a primary or secondary communication channel, providing critical redundancy and resilience to the overall data collection system. In the event of a localized network failure, satellite communication ensures continued data transmission.

5. Implementation Strategies

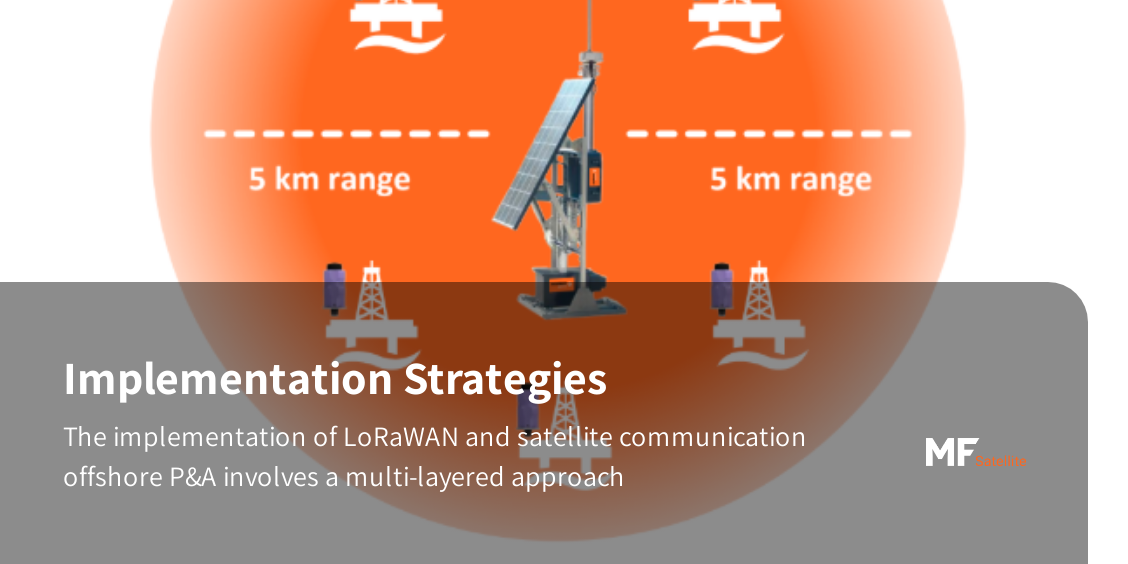

The successful implementation of LoRaWAN and satellite communication for offshore P&A involves a multi-layered approach:

- Sensor Deployment: LoRaWAN-enabled sensors would be strategically deployed on and around the P&A wellheads, monitoring critical parameters such as annulus pressure. These sensors would be designed for long-term, autonomous operation with minimal maintenance.

- LoRaWAN Gateway Network: A network of LoRaWAN gateways would be established on the offshore platform. These gateways would collect data from the individual sensors and aggregate it for onward transmission. Depending on the scale and complexity of the operation, multiple gateways might be networked together.

- Data Aggregation and Local Processing: The aggregated data from the LoRaWAN gateways undergoes initial processing and filtering at the offshore site. This local processing reduces the volume of data transmitted via satellite, optimizing bandwidth usage and reducing costs. Edge computing capabilities on the platform could analyze real-time data for immediate anomaly detection.

- Satellite Backhaul: The aggregated and processed data would then be transmitted via satellite to a secure onshore data center. This involves a satellite modem and antenna system on the offshore platform, establishing a reliable link to a geostationary satellite constellation with low power and reliable global data connectivity (see Viasat global L-band service).

- Onshore Data Management and Analytics: At the onshore data center, the received data would be stored, managed, and subjected to advanced analytics. Machine learning algorithms could be employed to identify trends, predict potential failures, and flag anomalies, providing actionable insights for preventative maintenance and intervention.

- Integration with Existing Systems: The P&A monitoring system would be integrated with existing offshore operational systems, such as SCADA systems, well integrity management platforms, and enterprise resource planning (ERP) systems, to provide a holistic view of the P&A assets and facilitate informed decision-making.

- Cybersecurity Measures: Robust cybersecurity protocols would be implemented across the entire data collection and transmission chain, from the sensors to the onshore data center, to protect against cyber threats and ensure data integrity.

Note: MinFarm has successfully deployed the above technology for working P&A use cases with very good results.

The MF-460-SERIAL-ATEX LoRaWAN Satellite Gateway acts as the central communication for all LoRaWAN-enabled Pressure Gauges and Sensors within the oil and gas field, securely transmitting data to the Customer Dashboard via secure satellite backhaul link. Read more

Summary: Bridging the Connectivity Gap

The success of remote operations, particularly in challenging offshore environments, hinges critically on robust and reliable communication. For P&A (Plug and Abandonment) operations, where real-time data is paramount for safety, efficiency, and environmental compliance, traditional communication methods often fall short.

Traditional communication infrastructure in offshore settings can be costly to deploy and maintain, often requiring extensive cabling or dedicated microwave links. Furthermore, the inherent remoteness and harsh conditions of these environments can lead to signal degradation, interruptions, and limited bandwidth. These limitations can significantly impact the ability to monitor equipment, transmit critical sensor data, and coordinate personnel, ultimately leading to operational delays, increased costs, and elevated risks.

The need for a more agile, cost-effective, and resilient communication solution is evident. This gap is being addressed through the strategic integration of advanced wireless technologies, specifically LoRaWAN (Long Range Wide Area Network), and satellite communication. This synergistic approach allows for the efficient collection of diverse data points from various sensors and equipment across the P&A site, followed by their reliable transmission to onshore control centers.

By combining the localized, low-power, and cost-effective advantages of LoRaWAN with the global reach and robust backhaul capabilities of satellite communication, the offshore P&A industry can achieve unprecedented levels of real-time monitoring, predictive maintenance, and operational efficiency, ultimately leading to safer, more environmentally responsible, and economically viable decommissioning operations.

Download the White Paper

This paper delves into a groundbreaking innovation: the synergistic combination of LoRaWAN (Long Range Wide Area Network) technology and satellite communication. This powerful duo can transform the landscape of offshore P&A data collection, offering operators an unparalleled blend of efficiency, reliability, and cost-effectiveness.